As a pillar industry of the national economy, manufacturing is undergoing unprecedented changes. With the rise of concepts such as Industry 4.0 and smart manufacturing, manufacturing is gradually transforming towards digitization, networking, and intelligence. However, hidden dangers in infrastructure have gradually emerged during this process. Numerous business systems, complex business architectures, and severe security situations have posed unprecedented challenges to the IT progress of manufacturing enterprises. How to effectively integrate these IT infrastructure resources, achieve seamless online and offline capabilities, and strike a balance between efficiency, cost, and ease of use has become the key for smart manufacturing enterprises to address the challenges of the digital foundation.

Low Resource Utilization

Low Resource UtilizationIn traditional manufacturing, IT infrastructure often suffers from idleness or inefficient utilization, leading to resource waste.

Complex Production Processes

Complex Production ProcessesStacked MES/APS/WMS and other production and manufacturing software have complex architectures and inconsistent clusters. The manufacturing production process involves multiple links, and there are obstacles to information transmission and collaborative operations between each link, which affects production efficiency.

Data Silos Phenomenon

Data Silos PhenomenonLack of effective integration and sharing of data among various departments within an enterprise results in data silos, making it difficult to leverage the value of data.

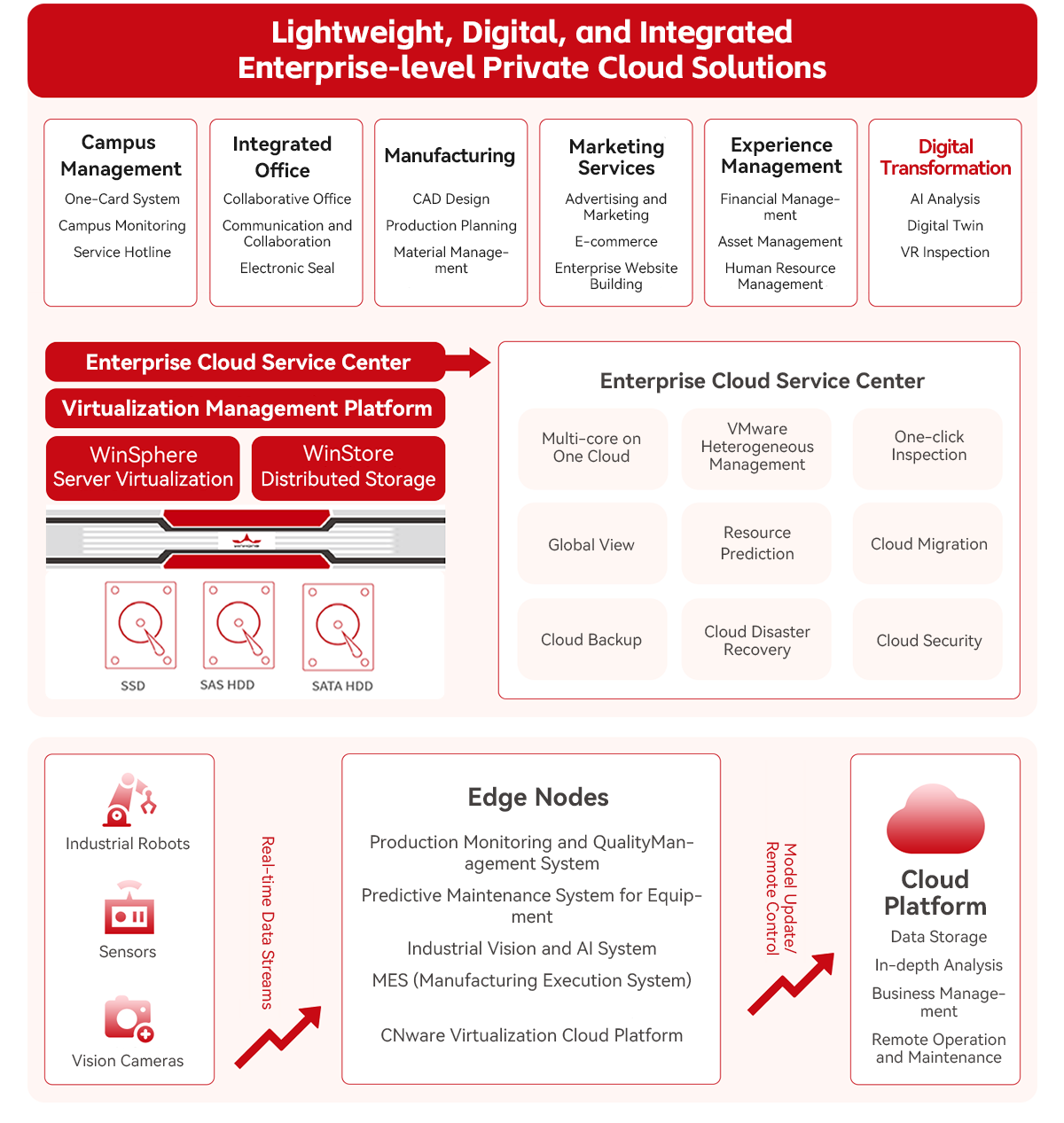

Industry public cloud

Industry public cloudUsing cloud computing technology, manufacturing enterprises can also build a shared cloud platform to realize the sharing of product manufacturing experience and the improvement of product manufacturing technology. The cloud big data platform is used to provide services such as data collection, analysis, mining, storage, and collaborative application, so as to promote the agglomeration of enterprise data resources, improve the level of precision marketing, and accelerate the development of industrial big data.

Industrial hybrid cloud

Industrial hybrid cloudUsing cloud computing technology, manufacturing enterprises can also build a shared cloud platform to realize the sharing of product manufacturing experience and the improvement of product manufacturing technology. At the same time, enterprises retain private clouds on-premises to host latency-sensitive and data-sensitive services. Combine the security and controllability of private cloud with the economy, efficiency and scalability of public cloud to reduce the cost of information construction, optimize the operation and management process, innovate business development, gradually realize the cloud integration of core business systems, promote cross-enterprise cloud collaboration, and continuously integrate into the transformation and transformation process of the open innovation ecosystem.

Resource pooling

Resource poolingThe main components of hyper-convergence are virtualization and distributed storage, which are integrated into the same set of servers, eliminating the complexity of traditional architecture and avoiding the problem that centralized storage is not easy to manage and scale.

Based on the Yunhong hyper-converged all-in-one machine, the information resource pool is built to provide a high-performance, highly reliable and scalable information resource pool architecture for modern manufacturing enterprises, and provide an ideal bearing environment for multiple sets of information systems of enterprises.

Enterprise Proprietary Cloud

Enterprise Proprietary CloudBased on the Wincloud cloud cloud platform, we will build an exclusive private cloud for manufacturing enterprises, promote the production and manufacturing business systems of enterprises to the cloud, flexibly and quickly use various cloud services of the cloud platform, and realize the centralized management and dynamic allocation of computing resources; Promote enterprises to efficiently and securely use cloud platform network resources through services such as load balancing to achieve smaller latency and faster network access. Promote the use of virtual desktops and application services by enterprises, and help users build cloud office systems that are more secure and lower maintenance costs. Optimize enterprise business processes, strengthen collaboration, make accurate decisions, and achieve standardized delivery of production capacity.

Customer Value

Increase Production Efficiency

Increase Production EfficiencyThrough a virtualization platform, flexible configuration and rapid adjustment of production lines are achieved, improving production efficiency and flexibility to meet market demands.

Reduce Costs and Increase Efficiency

Reduce Costs and Increase EfficiencyThrough a virtualization platform, centralized management and dynamic scheduling of IT resources are realized, reducing resource idleness and waste, and improving cost-effectiveness.

Enhance Security Assurance

Enhance Security AssuranceBuild a security assurance system based on a virtualization platform to strengthen security protection and compliance management, ensuring business security and stable operation.

Enhance Competitiveness

Enhance CompetitivenessThrough a virtualization platform, business innovation, process optimization, and intelligent upgrades are realized, enhancing the overall competitiveness and sustainable development capabilities of manufacturing enterprises.

7*24-hour Service Hotline

400-6300-003